The weight of forestry machines has steadily increased over the last few decades. The heavier they are, the shorter the length of time in which they can generally work without causing damage. Setting limits for the weight of the machines could help establish the conditions for fair competition between companies working in the forest. Technical innovations leading to better load distribution on the ground could benefit soil protection. A weight limit alone is however no guarantee of soil protection.

The forest soil is a crucial and irreplaceable factor in the production of wood as a renewable raw material. It provides a habitat for animals, plants, fungi and microbes, it stores and supplies water and nutrients and is a climate-relevant CO2-reservoir. The preservation of soil fertility is a key aspect of forest sustainability and responsible forest management. With the increasing mechanisation of forestry, especially in the second half of the 20th century, the deployment of machinery off the forest roads increased. This resulted in increased damage to the soil and to the remaining stand, prompting the forestry industry to introduce a systematic network of permanently marked skid trails. The movements of forestry machines and their tracks should be restricted to these skid trails.

Paradigm shift

After an increase in complaints in the 2000s about soil damage caused by forestry machinery also on skid trails, the Forestry Chiefs' Conference commissioned the German Centre for Forestry Work and Technology (KWF) in 2008 to develop a set of recommendations for soil-friendly timber harvesting. The KWF involved experts from science, forestry companies and machine manufacturers in this. A consensus was reached at the time that a permanent network of skid trails was needed. This was a paradigm shift, because previously access to the forest had only been based on the lifetime of a forest stand. Since then there has been an ongoing process to establish a permanent network of skid trails across forest stands and forest generations. This poses major challenges in terms of locating the old skid trails after storm damage, and clearing former skid trails of regeneration in the subsequent stand. The exact course of the skid trails must therefore be mapped in geoinformation systems.

The recommendations for action largely relate to measures designed to protect the soil on the skid trails and prevent damage. These may be organisational measures to reduce the stress and strain on the skid trails, but also technical adjustments to the machines.

Soil moisture is the decisive factor

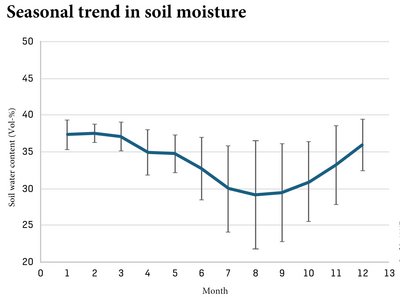

The load-bearing capacity of the soil depends primarily on the soil moisture at the time of it being driven over. If site mapping and many years of experience with the annual cycle of soil moisture are taken into account at the planning stage, felling measures on sensitive sites can be scheduled for periods with low soil water content. As one example of a situation requiring an organisational measure like this for soil protection in the forest, we can consider the seasonal variation in soil moisture in the Freising area (Fig. 2). There, felling on sensitive sites should be carried out as soon as possible after the growing season, but never in February, as this is when it is most likely to be the wettest.

Pressure and shear stress

When making adjustments to the machine to protect the soil, attention must be paid to both the pressure and the shear stress on the soil. Whereas in the past the focus was more on soil pressure and the adverse effects of compaction, today more attention is paid to preventing the shearing of soil material due to excessive slippage. Soil compaction on the skid trails is generally accepted, although the changes to the soil structure should not be so great as to impair the passability of the skid trails. It is particularly important that no ruts are created.

Rehabilitation and renaturation measures

If the passability for forestry machines is impaired, measures should be taken to restore it. The recommendations for action also describe rehabilitation and renaturation measures, the latter in the event that skid trails are to be abandoned again. The recommendations for action were compiled under the coordination of the KWF and the Federal Office for Agriculture and Food in the brochure “Soil Protection in Forests” (German only), published by the Agency for Renewable Resources.

Machine weights

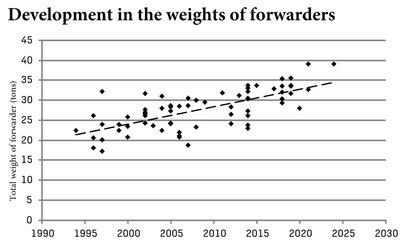

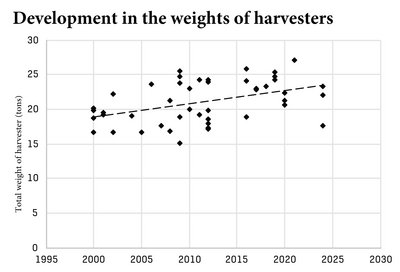

The weight of forestry machines has steadily increased over the years. This is documented by the KWF test reports (Figs. 3 and 4). The KWF tests the utility value of forestry machinery, which is then evaluated by a test committee. The increase in machine weights was greater for forwarders than for harvesters. According to the slope of the regression lines, the weights of forwarders have increased by 0.4 tonnes per year since 1995, and those of harvesters by 0.2 tonnes per year since 2000. There are of course also much heavier harvesters than those shown in Fig. 3. However, these are machines with caterpillar tracks, which distribute the load over a larger area.

Heavy machines should not be considered bad across the board: The heavier the machine, the better the traction between its wheels and the ground. One argument often put forward by forestry practitioners in favour of large forwarders is that fewer trips are required when machines with larger payloads are used. However, if the skid trails are to remain in place permanently, the frequency of the trips should not matter. The soil can only be compacted to a limited extent. If deep ruts are formed, either wet soil has been pushed out of the track by viscous flow, or soil has been sheared off by the tyres.

The profiles of forestry machine tyres are designed in such a way that any soil sheared off is deposited to the side of the tyres. Both viscous flow and soil shearing should be avoided at all costs. If you want to reduce the number of trips, it is better to reduce the number of timber assortments or extract mixed assortments rather than deploy larger machines.

If the ground is dry enough, even the heaviest machines cannot cause any damage. However, the periods of time during which the ground is sufficiently dry are short. In this context, Matthies pointed out as early as 2009 that the time windows for the deployment of forestry machines with high wheel loads are often not sufficient for them to be able to work profitably. The temptation is then great to use these machines in wet soil conditions, too.

Targets for vehicle access

It is generally better to set targets and leave it to the (forestry) industry to decide how to achieve them. The targets for vehicles moving off-road in the forest are clearly formulated:

- Vehicle access exclusively on skid trails

- Maintenance of passability for forestry vehicles

There is certainly still potential for technical improvements even today. If the connection between the tyre and rim is improved, the tyre pressure can be significantly reduced and the wheel load distributed over a larger area. Prototypes in practical use corroborate this promising possibility. On the other hand, there could be a rebound effect here, in that the potential could be exploited to deploy even heavier machines. It may therefore be helpful to introduce a limit on machine weights or, even better, on wheel loads. This would create a so-called “level playing field”, i.e. equal competitive conditions for forestry companies. Technical innovations could then benefit soil protection. The Bavarian State Forests decided as early as 2010 to no longer allow wheel loads exceeding 4.5 tonnes in state forests after a transition period.

It would certainly be an opportunity for more soil protection if other forestry companies were to follow suit. However, compliance with weight limits is still no guarantee that there will be no more adverse changes to the soil structure on the skid trails. The most important measures continue to be the monitoring of the prevailing soil conditions and the exploitation of any organisational measures and machine adjustments that can prevent soil damage. However, the setting of weight or wheel load limits for the machines would establish a framework for fair competition between companies in mechanised forestry harvesting.

Quick overview

- In the brochure “Soil protection in the forest” (German only), experts from science and practice provide recommendations for soil-friendly timber harvesting.

- The weights of forwarders and harvesters have steadily increased.

- A weight limit, particularly for wheel loads, could improve soil protection and provide the framework for fair competition between companies.