In the course of fully mechanised timber harvesting, forestry machines automatically collect large amounts of data. How can we use this data to optimise the timber supply chain? How must the timber supply processes be designed so that a continuous data flow is possible? What are the challenges and benefits of harvester data integration? These were the questions addressed by the project “PVDat - Process improvement in forestry supply chains using current information technology and the continuous use of harvester data”.

A common data standard: an opportunity

During felling and processing, a harvester automatically collects a great deal of information about the harvested timber, but also about the machine itself. These data are stored in a uniform structure, according to the international “Standard for Forest machine Data and Communication” (StanForD).

This general format (xml) with an open interface makes it possible to exchange and further process harvester data independently of the machine manufacturer. There are different file types with different messages for production control, production reports, control measurement and calibration, as well as for operational monitoring.

The production data with information on assortment, volume, tree species and geo-information are particularly useful for optimising the timber supply chain. Likewise, data from forestry companies, such as job orders and geo-information, can also be fed into the forestry machine system on the basis of StanForD.

Data flow along the supply chain

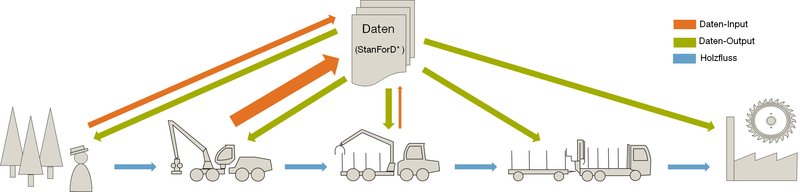

If we look at the entire timber supply process (Fig. 2), there are many ways in which machine data can be passed on and used, from the engaging of forestry companies, to the harvesting of the timber and its transport to the customer, to the invoicing and payment of forestry companies.

Right from the planning stage, the client compiles information that can be sent as a digital job order to the contractor and to the on-board computer of the harvester. The forestry contractor receives maintenance instructions and digital map material according to the StanForD and can use this data on his machines.

Geographical information systems can be used to pass on information on operational and property boundaries, rescue meeting points, trails, timber storage sites, reference points (biotope trees, poor terrain for machine access, ...) and, if necessary, trees for removal. The harvester operator can download these files on to his on-board computer before he starts felling and processing the trees.

Once the harvester driver has processed part of the area, he sends the newly created data on to the forwarders that follow. Data on the harvested timber (assortment, volume), stacking sites, and the route travelled are passed on, as well as any reference points that he has set for the forwarder driver. This step is carried out at regular intervals for each additional area harvested. The future exchange of information between harvester and forwarder drivers will thus be mainly digital and no longer via paper and on-site meetings.

At the end of the day, the harvester operator sends his data to the forestry company's system or forest owners' association's system, where it is processed further. The same applies to the forwarder driver, who passes on a daily report from the harvested area, giving the assortment and volume of the harvested timber.

Once the timber has been stacked, the forwarder driver creates a digital stack order with the volume, assortment and position of the stack. The operation manager can then record the stack in the system and make it available for transport.

The sawmills as customers benefit indirectly from the machine production data in that they receive more precise delivery forecasts for delivery ex-mill, or digital stack information, which they can process seamlessly in their IT systems and send as digital haulage orders to their hauliers in the case of purchase ex-forest road. The faster exchange of information overall improves the planning basis for all involved parties in the timber supply chain.

Challenges of data integration

To achieve a continuous flow of harvester data, digital work orders must first be created. For this purpose, an interface must be programmed in the software of the forest enterprise or forest owners’ association that makes it possible to generate StanForD-compatible harvesting and sorting instructions.

Furthermore, a consensual solution for the exchange of data must be found, based on the difficult definition of data ownership, and with the participation of all interested key actors and due regard to data protection. For this purpose, user interests and rights must be defined. Since not all forestry companies are equipped with the corresponding hardware and software, they need to upgrade accordingly.

The IT infrastructure/interface for data upload must also be provided by the forest enterprise or forest owners’ association, and a suitable data evaluation and display must be programmed according to their requirements. For the job orders and data evaluation displays, the project report suggests forms and tables that can be used by the software programmers for this purpose.

All those involved, but especially the forestry machine operators, must also be trained in the use of the software and in the new processes. Another challenge for data exchange that takes place in real time, rather than at the end of the day, is the poor mobile network reception in large parts of the forest. The question of who will pay the costs associated with all these issues must also be addressed.

Advantages of data integration

There are numerous advantages to continuous digital data exchange for those involved:

- The digital job order saves the harvester operator time configuring the harvester, and there are fewer errors due to media interruptions.

- Thanks to the digital map material, the machine operators can find their way around the stand better and thus have fewer questions for the operations manager.

- The forwarder driver can plan his trips better and thus approach skid trails in a more targeted manner. This also means that no more wood is forgotten in the forest.

- The forest owners’ association or forest enterprise receives information about the harvested timber earlier, and the data quality is better.

- Thanks to the improved planning basis, it is possible to act more flexibly in the process chain and to handle timber removal more quickly.

- The faster removal of the timber from the forest reduces the risk of a loss in value due to blue stain and bark beetle infestation and, in the case of an already existing bark beetle infestation, its further spread.

- With the flexibility gained, it is possible to react to fluctuations in customer demand and thus to improve market and customer orientation.

- The forwarder driver’s targeted approach to the skid trails means he avoids search and inspection runs and thus unnecessary driving on the ground.

Overall, the use of harvester data improves communication and the efficiency of the timber supply process.

Summary

As a result of StanForD, it is possible to obtain standardised forestry machine data. If the timber supply process is adapted to StanForD, a continuous data flow can be created. Only if all parties involved in the timber supply process are willing to exchange and mutually agree to reimburse the data can harvester data integration in the timber supply process in Bavaria succeed. This will benefit all stakeholders and result in the optimisation of the timber supply.