Storage under drying conditions was not intended for storing windblown timber. It was rather developed for pre-drying of roundwood. Due to the risks and costs of this storage method, it can not be recommended as a standard conservation procedure following calamities, especially for those without sufficient experience and knowledge of local conditions.

Click here to download the Spanish translation of this article (PDF-file)

Method

The aim is to dehumidify the timber to below fibre saturation point (approx. 30% timber moisture) as quickly as possible. The relatively dry logs then do not provide suitable living conditions for insects and wood-decaying fungi (which can cause e.g. red stripes and blue stains).

Risks

Dropping the moisture under fibre saturation point can lead to crack formation in roundwood. These cracks can limit further use and are entry points for fungi. Such entry points can also be caused through damaging wood while debarking.

Advantages

- Technically simple

- Simple forwarders with a crane can be used to build the stacks

- No investment costs

- No license/permit needed

- Ideal when customers demand pre-dried timber

Disadvantages

- Success of storage depends on climatic conditions and can not be actively influenced.

- If the timber dries too slowly, damage by fungi can occur. If it dries too quickly, crack formation and discolourations can result.

Evaluation and recommendation

The success of this storage method is highly dependent on site conditions and is influenced by changes in weather. The drying process can not be directly controlled (or only with difficulty, as experienced after "Vivian" and "Wiebke" 1990 showed). In Baden-Wuerttemberg, this method was not favoured after "Lothar" and was only used on a small scale.

The method can not be recommended as standard practice after calamities. Pre-dried logs should only be allocated where the customer explicitly demands them. Compliance with the preconditions is compulsory, but even where all preconditions are met, development of timber quality can not be controlled. Experience from Baden-Wuerttemberg shows that there is no guaranty whatsoever for the success of this storage method.

Preconditions

- Timber quality

- Only healthy, sparingly limbed, debarked, usually winter cut and larger dimensioned, homogenous conifer logs (where possible diameter class 3 or above) may be used.

- Time scope

- The time span between processing and debarking may not exceed three weeks; the logs should be in storage by March/April, depending on altitude (following winter storms).

- Debarking

- The logs have to be debarked as gently as possible, as damage to the stem may lead to fungus infection. The method can not be recommended for storing summer wood due to the higher risk of fungal infection.

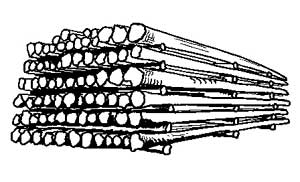

- Piling

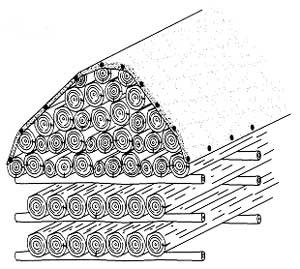

- Careful stacking, strong cross logs, large ground clearance, sufficient intermediate layers (25 – 30 cm), usually 2 to 5 layers, long side facing windward side.

- Storage location

- Exposed to wind, constantly ventilated, dry, warm, not shady. The logs may only be exposed to extreme solar radiation if storage duration is kept short.

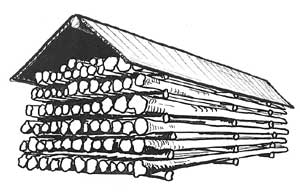

- Roofing

- Sufficient ventilation underneath the roof is needed. The roofing should extend over on the sides. Roofing is very expensive; the need has to be examined carefully. Drying and ventilation of the pile can be hindered near the roof if the roofing is mounted improperly.

Cross pile without roofing....

| ...and with roofing (maximum storage period with roofing one year), drawings: B. Textor, Forest Research Institute Baden-Wuerttemberg, Department for Forest Utilisation. |

Costs

The costs of the method amount to approx. 7,- to 13,- €/cubic metre (incl. debarking and transport). Extension of the storage period does not have direct effects on costs.

Storage duration

Roofed storage/medium-term: 1 year

Storage without roofing/short-term: three to maximum five months

| Tree species | Suitability | Comment | Duration |

| Douglas fir | Suitable | 12 (- 24) months | |

| Spruce | Good-Suitable | Needs to be dried and put into storage within three months, but red stripes and blueness possible | 12 months |

| Larch | Suitable | 12 (- 24 months) | |

| Pine | Less suitable | Risk of blueness |

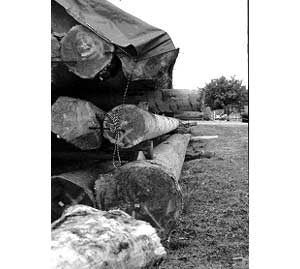

Drying of logs in roofed cross stacks, period of storage >5 months

Fig. 1: Securing logs with timber wedges.

Fig. 2: Wrong! Top layer not protruding.

| Fig. 3: Right. |

Before stacking

- Only prime cut logs;

- Preferably allow one to two weeks after debarking (pre-drying) ;

- Choose a site with firm, supporting ground, preferably free of vegetation;

- The site may be exposed to direct sunlight, the roofing regulates the microclimate within the pile;

- Use strengthened tarps with eyelets all around. It’s recommended to use two tarps (e.g. 8mx10m or 8mx12m each), as these sizes are often available ready-made (e.g. from cooperative agricultural suppliers, sailing supplies or outdoor shops; prices start at approx. 0,8 €/m²); silage film can not hold the tension continually and is therefore not recommended;

- Prepare big timber wedges with a band-saw (approx. 25 per stack) and pre-drill them for long nails.

During stacking

- Sufficient ground clearance by using large logs as under layer;

- Further stacking (2-4 layers) is best done in teams of two people; the cross logs (where appropriate top logs) can then be placed without shifting the crane truck;

- Only place wedges during stacking if logs seem to sit unstably, there is usually enough time for securing the stack with wedges after it is finished; wedges must be placed in any case to support the topmost, widest layer, on which the gable will be piled up; (Fig. 1);

- Logs damaged by debarking should be placed so that the damages face the inside of the stack;

- A protruding top layer is essential, otherwise the outside logs are at risk of permanent dampness (Fig. 2 & 3);

- Approved are stack sizes up to 150 cubic metres;

- Construction takes approx. 2.5 hours (not counting transport).

Roofing

- Roofing does not have to happen at once, but the timber should be protected from precipitation as quickly as possible;

- Start with one tarp, pull a bit over the top and fix along one side (nails through eyelets);

- Pull tarp over the stack, tighten, fold excess tarp back and put underneath the first tarp layer;

- Use pieces of lath wood to nail the tightened tarp to the other side; proceed in the same way with the second tarp;

- To secure the overlapping tarp, thread a safety rope (PE, approx. 6mm Ø, approx. -,30 € per running metre) through the eyelets of the top tarp and tie down to the stack;

- Roofing takes approx. 1.5 hours per stack;

- The roofing is principally maintenance-free (if applied properly).

Literature

- Schumacher, P.; Makas, M.; Wegener, G.; Eisenbarth, E.; Edelmann, P.; Bücking, M. (1998): Vorgetrocknetes Fichtenstammholz hoher Qualität. Holzzentralblatt Nr. 140, S. 2110 - 2111.

Forest Crises Management Advisory Guide

Back to the main page of the Forestry Crisis Management Advisor Guide: Overview of the different topic collections

Back to the article overview in the: Storm Topic Collection – Coping with Storm Damaged Timber