The triumph of plastics in practical silviculture in recent decades is difficult to ignore. Tree tubes in particular have now found widespread use. But there are also numerous other products that are either made of or contain plastics. These include browsing protection clips, deer rub protection spirals, plant pots, nets to stabilise the soil, for example, but also products added to planting substrates or used in root protection dipping.

However, it is also obvious - especially in the case of tree tubes - that some forestry operators do not take sufficient care when it comes to the proper disposal of these useful helpers. And yet legally, the issue is actually quite clear: substances or objects that no longer serve their intended use (the legislator speaks of their “original purpose”) must be disposed of properly. Only things that grew in the forest before can be left to rot there.

Bio-based, biodegradable and compostable: what exactly do these words mean?

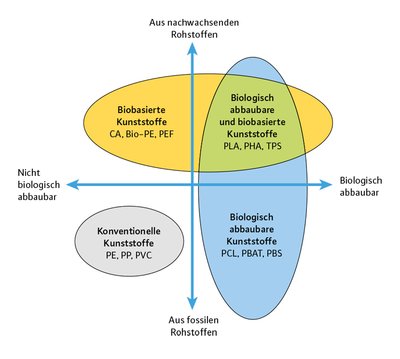

Plastic products are often labelled “bio-based” or “fully biodegradable”. But what is behind these terms? We will give a brief but by no means complete overview here for your orientation.

Let's start with the bio-based plastics. This term means that the basic materials from which the product is made are made from renewable raw materials and not crude oil-based. The raw materials are usually polylactide (PLA) or PLA blends and thus synthetic polyesters based on lactic acid. This is to be welcomed for reasons of sustainability, but tells us nothing about the degradability of the substances in and on the soil or in waste disposal facilities.

What is crucial here is the biodegradability of the substances. This term describes the ability of organic chemicals to be broken down biologically, i.e. by living organisms or their enzymes. There are industry standards for testing biodegradability. These define the conditions under which degradability is tested. So you have to look closely at the type of degradation a DIN standard describes in order to be able to judge what happens to a substance when it remains in or on the soil.

Let’s take an example: Often you will find the statement “compostable according to DIN EN 13432” on forest products and especially on tree tubes. The European test standard applied here examines composting under the ideal conditions of an industrial composting plant (90 % degradation within 6 months at 58 ± 2 °C). However, these are conditions that are never achieved in the forest. Obviously, there is no proof of complete decomposition. There are currently no certification standards on degradability under forest soil conditions. In practical terms, this means that even if a tree tube is labelled “bio-based and compostable according to DIN EN 13432”, it must be removed from the forest and disposed of properly when no longer needed or if it cannot be reused. Information on proper disposal is provided by local waste management companies.

Dismantling: as soon as possible, and as late as necessary

At a growth height of 1.5 - 2 m, the young tree in the tube may already have outgrown the competing vegetation and be big enough to escape browsing by game. But because it grew up in the greenhouse climate of the tube and was protected from the wind there, it does not yet have the necessary stability. If the tube is dismantled now, there is a risk of the tree keeling over without its support. The tube and support post should therefore be left with the tree for a few more years until it has stabilised in response to wind exposure and caught up on its root and thickness growth. However, since the tubes must certainly be removed before the plastic begins to break down into microplastics, it is important to ensure the tree always has the best possible, growth-accelerating light conditions to avoid any time pressure.

No alternative above ground?

Plastic products have undoubtedly become important helpers in practical silviculture. Nevertheless, we should think about how we can limit their use to what is absolutely necessary.

In practice, tree tubes in particular are used over large areas and in large numbers on cultivated areas because they offer protection from browsing. It is important to realise that tree tubes are only more cost-effective than fences for small cultivated areas or for wide planting distances. Having said that, fences protect not only the planted trees, but also the additional natural regeneration that develops. This can often increase the diversity of mixed tree species in the area, and the resulting higher number of plants can also be helpful for the quality development of the young saplings. So it pays to calculate and save costs, and at the same time to avoid plastics. There are calculation aids for this that allow a cost estimate to be made, and that show in which cases tree tubes, and in which cases fences are more cost-effective. Of course, the obligation to dismantle and dispose of the equipment after use also applies to fences.

In some places you can see tree tubes under the canopy of old trees or in the shade of birch trees and herbaceous plants. All too often the trees die in the tubes due to a lack of light. Under such conditions, you could just as well dispense with the tree tube entirely.

Fig. 5: This deer rub protection cover should have been disposed of as plastic waste years ago. Photo: W. Rothkegel (LWF)

In addition, there are now alternatives made of renewable raw materials for many plastic product applications. This is particularly true for browsing and deer rub protection. With tree tubes, too, there are various products already being trialled - and some of them are already available on the market. However, there are still some practical questions to clarify here, especially relating to light permeability, durability and the growth behaviour of the plants. We would nevertheless like to explicitly encourage forest owners and operators to try out these alternatives and to share their experiences with the manufacturers. Only in this way can a continuous process of development and improvement be guaranteed.

Some forestry products made from plastics can also be reused. This is especially true of tree tubes. Durable and therefore long-life products should be used here. When buying the products, care should be taken to ensure that the closure systems are designed to facilitate reuse. Products that can be conveniently folded up and thus do not take up too much space during transport are also favourable here. Plantations with tree tubes should be checked at least once a year, as should fences.

... and under the ground?

In the forestry sector, plastics are also offered in various forms for use in the soil. Unlike above-ground use of plastics, the problem here is that their removal from the soil is barely possible in practice. Here, too, we would therefore like to briefly highlight the different areas of application and possible alternatives.

In this context, ball-planting should be mentioned. Here there are systems on the market in which a thin net of bio-based plastic is wrapped around the growing substrate and root ball. The net is certified according to the above-mentioned DIN EN 13432 regulation and cannot be removed from the root ball after planting. Due to the uncertainty of their degradability in the soil, such planting systems are not eligible in Bavaria for funding support under the silvicultural funding programme “WaldFöPR”.

Another area in which plastics are offered for use in forest soil are the so-called superabsorbent polymers or hydrogels. These substances, which are also used in nappies, for example, are able to store large amounts of water, which is then supposed to be available to the plant during dry phases. They are added to growing substrates in the form of powder, granules or pills, or laid in the planting hole during planting operations. These superabsorbents are also used as evaporation protectors when the roots of forest plants are dipped for protection. Under current legislation, hydrogels may also be added to forest soils as additives to improve the quality of the soil, provided the requirements of the Fertiliser Ordinance are met. To our knowledge, there is no certification to date for the biodegradability of these substances under forest soil conditions. Their use thus leads in Bavaria to projects being excluded from eligibility for funding support measures such as the WaldFöPR scheme.

Drought damage to forest plantations can be caused by a lack of water in the topsoil due to a lack of rainfall. More common causes are however dried out root hairs, mould infestation, or excessive root pruning. Poor planting quality, the lack of protection from evaporation during transport and interim storage over excessive lengths of time can further increase the extent of the damage. The vast majority of Bavarian forest soils has a good to very good natural water storage capacity. A lack of soil moisture due to insufficient rainfall cannot be compensated for by the use of hydrogels on the vast majority of sites, or only in the short term. Due to the uncertainty of the biodegradability of hydrogels under forest soil conditions, we recommend that forest operators consider very carefully whether their application in the forest is really necessary. For root protection dipping of the young plants in the nursery, we recommend proven preparations based on brown algae (alginates). This protective treatment should be a standard component of every tender, planting material order, and quality control measures upon delivery. It is currently eligible for funding in Bavaria under the WaldFöPR programme.

Summary

Plastic-based products currently play an important role in practical silviculture. Knowledge about the decomposition of plastic products under forest conditions is generally still poor. Certification norms for degradability under forest soil conditions do not currently exist. Foresters and forest owners should thus consider very carefully whether their use makes sense or whether there are plastic-free alternatives. After use, all plastic products must be removed from the forest and disposed of properly in accordance with waste management regulations.