Fig. 1: Some of the logs in the study were processed by harvester to find out if there was a preventative effect.

(Photo: Gregor Seitz)

The current bark beetle calamity shows clearly just how important bark beetle management is, particularly in the case of the European spruce bark beetle (Ips typographus) in spruce forests. The share of mechanical processing has increased considerably in recent years within the context of “clean” woodland management and the sanitation of infested trees. It was thus reported from the ForstBW forest district “Südschwarzwald” (southern Black Forest) that about 90 % of the storm-damaged and bark beetle-infested timber that arose during the calamity in 2020 was processed by harvester (by word of mouth,. Emmerich 2021).

In this article, we take account of the great importance of this technology by examining the machine processing methods and relating them to established methods of bark beetle management. The background to this is a recently completed research project on the risk of infestation with the European eight-toothed spruce bark beetle spreading from spruce trees mechanically processed by harvester. A summarised presentation of this study is followed by recommendations on how mechanical processing can be integrated in bark beetle management.

The issue

Forestry practitioners were asking whether and to what extent the apparent mechanical force exerted by the harvester head (delimbing knife, feed rollers and measuring wheel) considerably reduces the suitability of the bark as a breeding site or substantially destroys already existing beetle broods.

As the bark is perforated, deformed, crushed, peeled off or cut into during the processing, this would appear to be a logical conclusion (Fig. 2). Ultimately, the question was whether logs processed by harvester still needed to be prioritised for further sanitation measures.

Fig. 2: Hole in the bark showing breeding galleries of the European spruce bark beetle, perforated by the feed roller.

(Photo: Gregor Seitz)

Study

From 2018 to 2020, several studies were carried out in the current forest districts of Oberland, Südschwarzwald and Westlicher Schwarzwald of the Baden Württemberg state forest company ForstBW AöR. The trees selected there came from homogeneous spruce stands over 70 years old and belonged to Kraft’s crown classes 1 or 2 (crown development classification). They had a straight trunk, a homogeneous crown length, and a BHD between 30 and 70 cm. These uninfested trees were felled using a motor-manual method, skidded carefully to the forest road, and then measured and cut into 4-5 sections of 5 metres in length. A total of around 500 log sections were examined in this way. Some of the logs in the study were processed immediately by harvester to establish whether there was a preventative effect. To determine the efficiency of the method as a treatment for bark beetle infestation, the remaining logs were processed by the harvester only after being colonised and at different stages of the beetles’ development. For this purpose, these spruces were baited with pheromones to ensure the logs were colonised as evenly as possible. A distinction was made between

- motor-manual processing as the untreated reference group (Mm),

- partially mechanised processing with the harvester head running over the log (Tm),

- modified partially mechanised processing with the harvester head running over the log a second time after approx. 90° rotation of the log around its stem axis (Tm_Mod) and

- partially mechanised processing with the so-called “debarking head”, a harvester head equipped with debarking knives and modified feed rollers, which enables rotation around the longitudinal axis of the log (Tm_Dbh).

The bark shorn off in the Tm_Mod and Tm_Dbh variants was collected and also examined for viable adult beetles. For this purpose, the processing was carried out over a tarpaulin (on the forest track) and the bark was stored in gauze bags in close proximity to the log until the end of the trial.

After processing, the logs were stored on supports, injuries to the bark were recorded, and then a log eclector constructed from gauze nets was built around each log to collect the hatching beetles (Fig. 3).

A strip of net impregnated with insecticide inside the eclector killed the adult beetles that emerged from the trunk. These could then be collected and counted once the eclectors had been dismantled. The results of the individual variants could then be compared.

Fig. 3: Trunk sections in the net eclectors.

(Photo: Gregor Seitz)

Results

The proportions of deformed or completely sheared off bark differed significantly between the methods investigated and the motor-manual processing; but there were also striking differences between the respective partially mechanised processing variants. This resulted in different rates of efficiency in killing the insects at the brown stages (young beetles, adult beetles) and white stages (eggs, larvae and pupae).

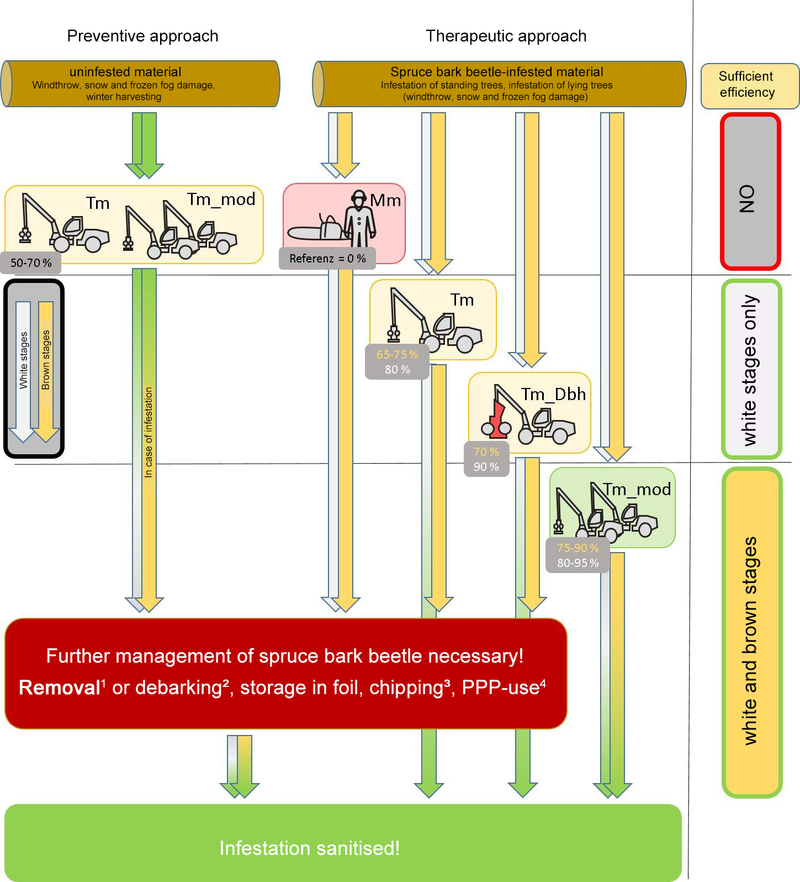

Each of the three partially mechanised processing variants tested resulted in reductions of the insect presence with an efficiency (WG)* of ≥ 80 % when white stages of the insect were present. For beetles in the white stages, these processing variants thus achieved an adequate degree of efficiency for a therapeutic measure, comparable with the generally accepted level of efficiency expected of plant protection products (PPP). For beetles at the brown stage (developed young beetles), only the variant Tm_Mod achieved a rate of efficiency of ≥ 80 %. Compared with this, the rate of efficiency of the Tm and Tm_Dbh variants was somewhat lower at 65-75 % (Fig. 4 Decision tree). It should also be borne in mind that large pieces of the bark are peeled off during the processing, especially with the Tm_Mod and Tm_Dbh variants. If young beetles (brown stage) are already present at the time of processing, they remain with the peeled off bark in the stand and continue to present a risk to the forest!

*The rates of efficiency of the treatment variants in comparison with the motor-manual processing as a reference procedure are determined on the basis of the number of hatched spruce bark beetles relative to one square metre of the mantle (area) of the logs (formula according to Abbott (1925)): = 100∗-/ (w = Efficiency, u = number of animals in control group, b = number of animals in treatment group).

Preventive processing by harvester, i.e. the processing of uninfested wood, also resulted in an insufficient rate of efficiency in comparison with the efficiency expected of plant protection products. For all the variants examined, the efficiency of preventive processing was between 50 and 70 %. Although the supply of suitable breeding space was reduced, the timber could thus still be extensively colonised (Fig. 4 Decision tree).

Summary

The study shows that processing with a harvester is generally preferable to processing by the motor-manual method, not only because of the higher level of work safety, the lower harvesting costs and the higher processing output, but also from the point of view of forest protection. If motor-manual felling is unavoidable, e.g. due to wide distances between extraction tracks or to protect the stand, an attempt should be made to integrate a harvester in the processing (partial mechanisation). The results show that infestation is significantly less likely to spread from logs that have been processed by harvester, and that there is thus less of a threat to the forest from logs processed in this way. However, it should be borne in mind that it is only at the time of the development of the first generation in spring that exclusively white stages of the beetle are present. After the appearance of the first brown beetles, there are usually both white and brown stages of the insect present at the same time during the rest of the year, due also to the establishment of sibling broods!

At the brown stage, only the processing variant Tm_Mod achieves a sufficient rate of efficiency. For this reason, further measures are necessary to manage the beetles after the Tm and Tm_Dbh treatment variants once there are beetles at the brown stage (Fig. 4 Decision tree). In this case, timely removal to the sawmill, storage at a sufficient distance from coniferous stands or storage in deciduous stands, storage in foil, debarking, or chipping should be considered. As a last resort, an approved plant protection product can be sprayed to sanitise the infested timber before the beetles can fly on to other trees. In the case of both the Tm_Mod and Tm_Dbh variants, it is necessary to collect and destroy the peeled off bark when beetles at the brown stage are present, as they are mature enough to survive and may thus remain in the stand with the peeled bark and cause secondary infestations.

The positive effects of the Tm_Mod and Tm_Dbh variants in terms of forest protection are offset by a reduced processing capacity compared with the conventional Tm variant. The Tm_Mod procedure also requires an increased level of concentration and skill on the part of the harvester operator. With the Tm_Dbh variant, the required contact pressure and the diagonally positioned shanks on the feed rollers can result in increased damage to the wood body, which may have a negative influence on the timber revenues.

The decision for or against mechanised processing must ultimately be made by the forest owner himself after weighing up the advantages and disadvantages of the individual methods described here. Financial support under the “debarking of damaged wood” measure in accordance with Part F of the “Administrative Regulation on Sustainable Forest Management” (for the elimination of the consequences of extreme weather events in the forest) is not available for any of the three harvester-based processing methods described here.

Fig. 4: Decision tree on processing and European spruce bark beetle management. The percentages describe the achieved rate of efficiency (WG) of the respective method and for the respective stages of beetle development (brown script = processing at the brown stage, white script = at the white stages, black script = reference and preventive approach). The efficacy generally required of a plant protection product (PPP) is achieved from a rate of efficiency of 80 % (Federal Biological Research Centre for Agriculture and Forestry BBA 1980). (Source of the pictograms shown: Kuratorium für Waldarbeit und Forsttechnik KWF)

- To the sawmill, wet storage, dry storage, deciduous forest stands (at a sufficient distance from spruce stands)

- If beetles at the brown stage are present, the bark must be collected and removed or covered!

- The wood chips must also be removed or covered!

- PPP use possible as a last resort, by spraying the woodstack before the beetles fly out of it, certification systems must be observed

Mm: motor-manual, TM: partially mechanised, TM_mod: modified partially mechanised, Tm_dbh: partially mechanised with so-called "debarking head"