The Norway spruce (Picea abies) was the tree of the year for 2017. It has even been named as the breadbasket tree of Bavarian forestry due to its multifaceted range of applications.

Description of the wood

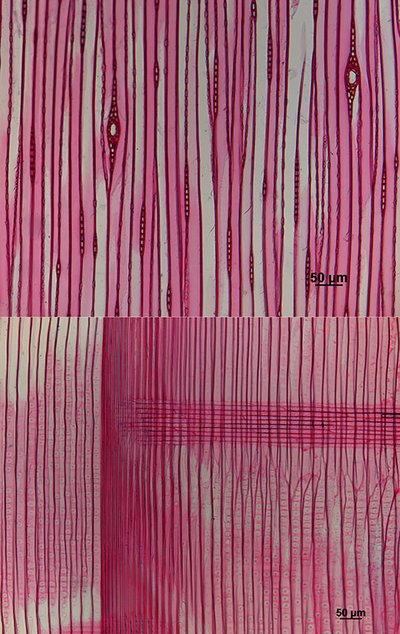

Fig. 7: Images from an optical microscope: flat sawn (top) with singly arranged and wide wood rays: In the quarter sawn, or radially cut (bottom), the following can be seen: Early wood tracheids with large bordered pits, growth ring border and narrow, lumen-rich latewood tracheids. The wood ray is noticeable in radial cuts as transversal orientated cells.

The wood of the spruce is evenly bright when freshly cut, at the most it displays a yellowish white color. Due to its similar coloration between heart- and sap- wood it belongs to the "mature heartwood" trees (Figure 1). When the wood ages it darkens to a yellowish-brown hue under the influence of light. Spruce wood cut longitudinally to the stem displays the typical conifer figure (Figure 2) and striping (Figure 3). The width of the growth rings are dependent on site characteristics and can either be narrow or wide but are always very distinguishable from one another. The transition from springwood to summerwood is generally fluid (Figure 4). Fresh spruce wood has a resinous odor and shows a silky shine when planed.

Tracheids make up about 90-95% of the cellular tissue. The main difference between spring- and summerwood, the cell wall thickness, becomes noticeable under a microscope (Figure 6). The density of the summerwood is of essential importance for the firmness of the wood and its width is constant in relation to the entire width of the growth ring. This is the reason why spruce trees with narrow growth rings possess a higher density since the proportion of summerwood tracheids is higher. In addition to the axially orientated tracheids spruce wood also has axially (Figure 5) and radially orientated resin ducts (Figure 7).

The wood rays of the spruce are made from two types of cells. The central, thick-walled parenchymal cells are lined by one or two rows of smooth-walled transverse tracheids.

Over-all character

Straight grained, bright conifer wood without heartwood discoloration. Distinct spring and summerwood areas with well marked growth ring borders; There is a fluid transition from spring to summerwood inside of a growth ring. Freshly cut spruce possesses a resinous odor. With exposure to the air the wood darkens to a yellowish-brown hue.

Characteristics

Spruce wood is classified as a mid-weight with a density of 0.46 g/cm3 at a wood moisture content between 12-15%. However, the weight is dependent on the width of the growth rings and has a wide range of variation (Table 1). As a result, it is only permitted to use conifer wood for construction purposes which possess growth rings between four and six millimeters in width (sorting class S13 and S10, respectively).

Due to the good characteristics in firmness and elasticity (Table 2), spruce wood lends itself exceptionally well for use as a construction timber. It does not swell much and after drying it features predominantly good dimensional stability (Table 3). Substantial deformations only occur from trees with pronounced spiraled growth or high amounts of compression wood.

Spruce does not possess a natural durability and is not very resistant to weathering if the wood is left unprotected or untreated. If the wood has contact with the soil it can even decompose very quickly. Outdoor the wood has to be protected either through construction measures or through an appropriate treatment with chemical wood preservatives or protective coatings.

Due to the low ability for the wood to absorb moisture it is extremely difficult to impregnate the wood, even under pressure (sapwood is limited and heartwood hardly impregnable). A sufficient amount of a protective agent can be impregnated in a boiler pressure chamber after a mechanical pretreatment (e.g. through drilling, slice perforations or pin-prick perforations). The poor penetration of liquids also means that spruce in wet-dry climates and those which are exposed to short-term influences of dripping water only very slowly reach a wood moisture content over 20% in which fungal infestation can arise.

Spruce wood can be dried naturally and technically very quickly. With tension wood as an exception, spruce wood hardly cracks and warps. Picea abies can be easily processed with typical hand and machine tools. The wood can be sawed, planed, shaped with a router, drilled and sanded equally well; it is easy to cut and chop and for veneer production it can also be peeled and cut with ease. Joining pieces with nails and screws is straightforward and glueing with thermoplastic and thermosetting adhesives is not a problem. A high frequency of knots, the presence of resin pockets, spiral growth or the formation of tension wood can be disadvantageous.

Spruce can be painted easily with all standard glazes, satin finishes, varnishes and even clear and colored waxes. Solely the resin pockets which have been cut into can be a disturbance and need to be pretreated. Spruce wood can be stained exceptionally well since the staining process brings the decorative contrast from early and late wood to full light; the same holds true for colored glazes. Other popular surface treatments include sandblasting, brushing and burning.

Spruce wood is hardly reactive due to its extract content of 2.3%. Iron metals do not corrode, however they can produce a weak graying in moist wood. No discolorations arise from contact with copper or brass. When the wood sets in concrete no impairments arise. The spruce is fairly resistant to weak acids and bases.

Field of application

Spruce wood is marketed as round wood, palisades, cut lumber, sometimes as veneer (usually sliced), as construction timbers and lastly as wood chips. In terms of volume it is by far the most important source of construction timber in central Europe (Figure 8).

It is traditionally used as solid wood in interior design. Currently glued, single-layered and triple-layered solid wood panels are preferred for interior wall and ceiling coverings as well as furniture fronts. Carpenters use the wood to make doors and windows. Due to the low hardness of the wood (Table 2), plank flooring made from spruce is rarely in demand. However, the tree species still has a relevance as a middle or sub-layer in multilayered parquet floors.

Spruce lumber is commonly used as siding on the exteriors of single family homes. However, if the wood is not protected a grey or black discoloration will arise due to UV weathering. Coatings with protectants increase the durability of the wood. When the wood comes into contact with the ground (gardens, landscaping, utility poles), it has to be chemically pretreated with a protectant.

There is a high demand for spruce for packaging (boxes, pallets, punnets/crates) and low quality wood is suitable for such purposes. On the other hand, a traditional usage of the wood is dependent on high quality and a good selection: tonewood for stringed and keyboard instruments (Figure 9). Straight grained spruce wood with narrow growth rings has been a dependable material for the ongoing craft of building high quality instruments.

Solid construction lumber made from sorted, dried and finger joined conifer sawn lumber has taken on a significant role (Figure 10). In timber engineering today, bar-shaped logs made from glued laminated timber, curved glulam elements and cross laminated timber (Figure 10 and 12) dominate the market place. Spruce can also be used for the production of laminated veneer lumber (Figure 11).

Engineered spruce wood and the by-products of the lumber industry are, in addition to waste paper, the main raw material for the production of fiber and pulp products such as boards of composite wood (e.g. particle board, medium-density fiberboard, low density fiberboard). Wood chips are the basis of industrialized energy production from cellulose (wood chip furnaces, thermal power plants); Briquettes are formed from sawdust and wood shavings and are also used to produce energy.