Health impact of fine particulate emissions

According to the [German] Federal Environment Agency (UBA), fine particulate matter emissions (PM 2.5, i.e. airborne dust particles with a diameter < 2.5 µm) decreased from 202,000 tonnes in 1995 to 81,000 tonnes in 2020, i.e. by 60 %. Particulate matter emissions from households and small consumers also fell during this period from 40,900 to 21,800 tonnes, a decrease of 47 %. This value includes all domestic firing systems, i.e. including oil and gas boilers.

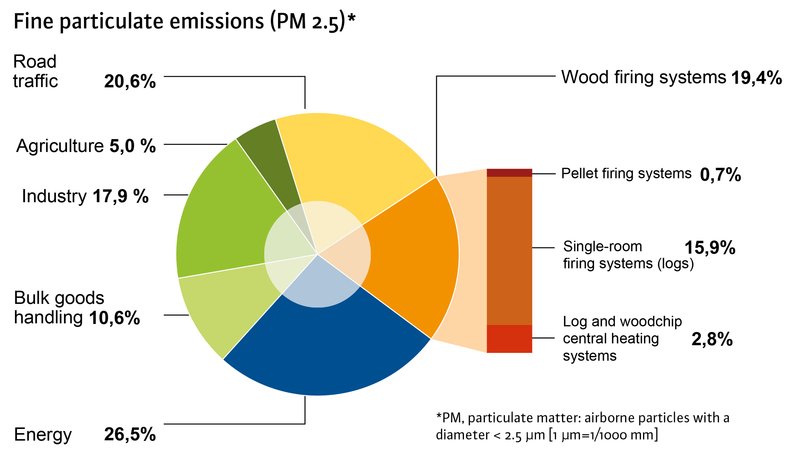

It is a fact that the air in Germany has become cleaner and cleaner over the past decades. What has changed are the required standards of air quality, which have become more and more stringent. Another fact, however, is that wood firing systems are responsible for almost one fifth of particulate matter emissions in Germany (Fig. 1).

Dust separators or other technical optimisations in new wood firing systems significantly reduce or virtually eliminate dust and fine particulate emissions. Operating errors with single-room log firing systems can on the other hand cause high particulate emissions, especially during the lighting process, or if the fuel is not sufficiently dry. Air flow control errors can nowadays be reduced to a minimum by technical means, through automatic combustion air regulation. The Technology and Support Centre (TFZ) has published a series of explanatory videos on the correct operation of log firing systems.

Modern central heating boilers fuelled with pellets or wood chips produce almost no particulate emissions. So when it comes to heating with wood, it all depends on the system being used, how it is operated, and whether the fuel being used is suitable. Fine particulate matter emissions are not a fundamental argument for excluding the use of wood-firing systems.

In the recent past, the set standards for emissions have been made considerably stricter by several ordinances on the implementation of the Federal Immission Control Act (BImSchV). The 1st BImSchV ordinance regulates replacement obligations, measurement procedures, type tests and emission threshold values for small and medium-sized firing installations with a rated heat output of 4 kW to 1000 kW. The 13th ordinance on the other hand regulates the use of large firing installations with a thermal output of more than 50 MW. The 44th ordinance sets the threshold values for installations with a thermal output of 1-50 MW, and took effect at the end of 2018. A survey of 1,000 private households in the course of the Energy Wood Market 2020 study showed that the regulations of the Immission Control Act are effective, and that the replacement of old wood-firing systems with modern systems is in full swing.

Climate impact of CO2 emissions from wood combustion

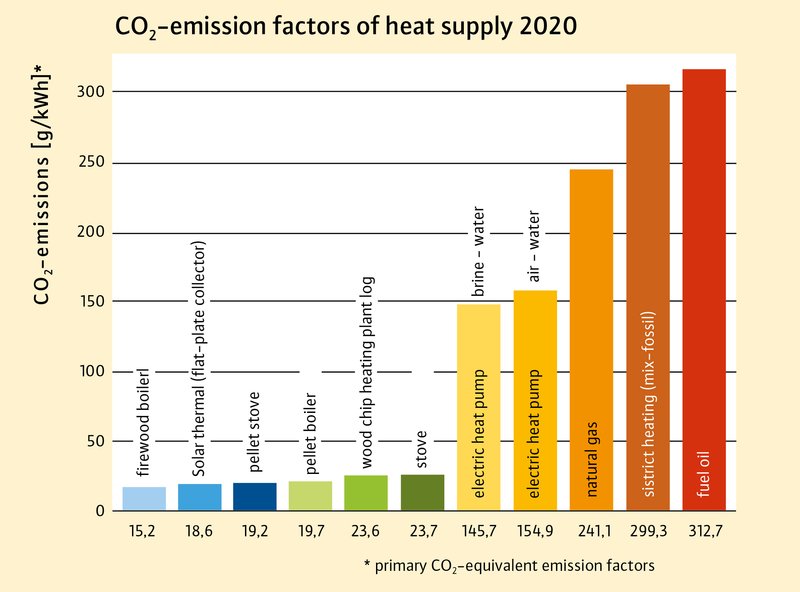

Figure 3 shows the climate impact of emissions from wood combustion in comparison with other heating systems: It is clear that the emissions per kilowatt hour of heat from all three types of wood firing are in the order of magnitude of solar energy, and significantly lower than those of oil or natural gas systems, and also than those of heat pumps. The emissions that occur upstream in the supply chain - i.e. during logging, transport and processing - are also included in the calculation for the wood combustion systems. As long as the quantity of carbon stored by the forest does not decrease, but maintains its level or continues to increase as before, the CO2-emissions from wood combustion do not burden the carbon emissions balance.

The use of wood for energy in Europe is subject to strict controls to ensure its sustainability. At the end of 2021, the Biomass Electricity Sustainability Ordinance took effect in Germany. This is the national implementation of Article 29 of the European Renewable Energy Directive (in short: "RED II").

In essence, the ordinance states that biomass heating plants with a total thermal output of more than 20 MW require certification in order to remain eligible for funding. It also says that, as of 1 January 2022, the sustainability of forest biomass used in such heating plants must be documented. For the use of the biomass to comply with the sustainability criteria set out in the ordinance, it must be shown that the logging is legal, that the forest is being sustainably regenerated, the soil quality and biodiversity are being preserved, and protected areas are being respected. Recently, a further revision to the Renewable Energy Directive was agreed. This will presumably also require sustainability certificates for smaller heating plants.

Climate impact of particulate emissions from wood combustion

The opinion is increasingly spreading that, as well as representing a health hazard, the fine particulate emissions produced by wood combustion have a harmful effect on the climate. Scientists at the TFZ have therefore compared the impact of heating with wood on the climate with that of other heating systems, assuming that fine particulate matter has an effect on the climate. They have come to the conclusion that heating with wood, even when particulate emissions are taken into account, produces lower greenhouse gas emissions than other heating systems (e.g. heat pumps with the current mixture of electricity sources).

In fact, particulate matter curbs the rise in atmospheric temperature. Fine particles are considered to be aerosols. "Aerosols (...) in fact counteract greenhouse gases. They partly mask global warming - according to the IPCC by about - 0.9 W/m2, and thus by about one third of the radiative forcing of greenhouse gases since 1750. The reduction in the warming due to aerosols has however declined in recent decades. Aerosols had the strongest effect on temperature values around 1980, when they reduced it by - 0.85 °C. By 2010, the reduction was only - 0.72 °C, with sulphate aerosols alone contributing - 0.55 °C. The global mean temperature in 2010 would (...) have been reached by around 1970 without aerosols." (Klima-Wiki). Particulate matter thus has more of a cooling effect on the climate.

Efficiency of wood as a fuel

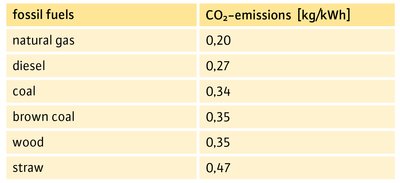

Critics of the use of wood for energy also argue that CO2 emissions per unit of energy from wood-firing systems still exceed the CO2 emissions from fossil fuels.

It is true that less CO2 per unit of energy provided is released by the burning of natural gas and oil than by the burning of wood (Fig. 4). However, the CO2 released from the burning of fossil fuels is CO2 that has been locked up in the ground for many millions of years and that is re-entering the carbon pool of the atmosphere and biosphere, thus increasing the total amount of carbon in this pool. This is not the case with CO2 from wood. Once fossil carbon has entered the carbon pool of the atmosphere and biosphere, it is very difficult to remove it again. Any additional input of carbon from fossil sources into the carbon pool of the atmosphere and biosphere creates a long-term problem.

It is also necessary to take account of the different energy requirements for extracting the fuels. This is likely to tip the balance further in favour of wood, especially if we compare the relatively low energy input for wood harvesting with the large-scale industrial plants for the extraction or further processing of fossil fuels.

Greenhouse gas balance takes account of wood combustion

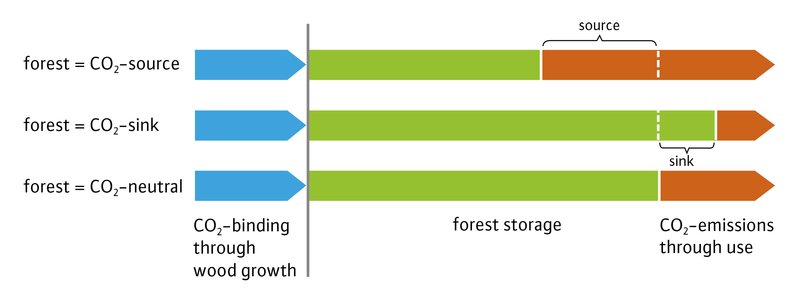

In greenhouse gas reporting, no greenhouse gas emissions are calculated for the use of biomass and thus also wood in the "Energy" sector. This does not mean that the CO2 emissions from the combustion of wood are not taken into account in the reporting, however, because the extraction of wood from the forest, including the extraction of wood for energy, is already counted as CO2 emission. This use of biomass is accounted for in the "land use, land-use change and forestry" sector (LULUCF). In the LULUCF sector, the emissions generated by timber extraction can be offset by the growth of wood (= binding of atmospheric CO2).

As long as the forest’s carbon stock does not shrink, timber extraction and with it the use of wood for energy is climate-neutral (bottom bar in Figure 5), so the atmosphere is not burdened with additional CO2 through the burning of wood. If the amount of timber extracted is lower than the wood growth increment, the forest even acts as a CO2 sink (middle bar in Figure 5). Conversely, however, the forest becomes a source of CO2 (top bar in Figure 5) if more timber is removed than grows. The harvesting of timber for material use counts as an inflow to the carbon storage in wood products. If this inflow is greater than the outflow from the carbon storage of wood products, this storage also acts as a CO2 sink.

The effect of time

Climate experts believe that the next few years are going to be crucial for the achieving of our climate goals. They say it is essential that we begin immediately to reduce CO2 emissions. Critics of the use of wood for energy argue that for the same amount of energy, it is better to emit slightly less CO2 from fossil fuels into the atmosphere, than to emit a slightly larger amount of CO2 from the biosphere. They are thus of the opinion that the wood increment (which is shown as a carbon sink in Figure 5) should be left in the forest, and that fossil fuels should be used instead. In the short term, such considerations are entirely justified - but only if the CO2 really does remain in the forest.

It must not be forgotten that both deadwood and forest residues left in the forest after harvesting operations are eventually largely decomposed again by microorganisms. The CO2 originally bound in the wood is released again through the decomposition process. If forest residues are not used for energy and instead remain in the forest, most of the CO2 bound in them will very soon end up in the atmosphere anyway. But it is not just forest residues that are a significant source of wood fuel.

When roundwood logs are processed into beams and planks at the sawmill, wood residues such as wood shavings and sawdust are also produced. If these are not used for energy but composted instead, the majority of the CO2 bound in them is also released into the atmosphere. Consequently, a renunciation of the use of wood for energy does not increase the storage of CO2 in the biosphere. On balance, the renunciation in fact leads to more CO2 emissions: those from the burning of fossil fuels and those arising from the biodegradation of forest residues or the leftovers from wood processing.

A complete renunciation of wood use would not be expected to have a positive effect, either. It would mean that wood products would also have to be replaced by other materials - and this in turn would usually be associated with a considerably higher consumption of fossil fuels. The amount of CO2 stored in harvested wood products (HWPs) such as roof trusses, furniture and wooden flooring would also gradually shrink if new wood products were no longer being continually produced as substitutes. The carbon stock in wood products would thus become a source of CO2. A positive effect of usage stops on the forest carbon stock itself could only be expected if it were possible to expand the forest carbon stock. In our opinion, this option is however unrealistic.

Fig. 6a and b: Whether it is deadwood or sawdust - both release CO2. In the case of deadwood, this takes place through the biological degradation of the wood through microorganisms; in the case of sawdust, either through its utilisation for energy, or composting (Picture: Gero Brehm, AELF FFB (left); Michael Lutze, LWF (right)).

Comparison of C storage potential in forests with energy substitution

Another argument often put forward against wood energy is that increasing forest C storage binds more CO2 than is avoided by substituting wood for fossil fuels. However, this argument overestimates the possibilities for building up further stocks and the resulting potential increase in storage of CO2 in the forests.

Although a stock build-up of more than 1,000 m³ of wood per hectare is possible in some forest stands, this is not the case at landscape or federal state level. At these levels, there are forest stands of all ages, so that the average stocks are much lower. We assume that the maximum achievable wood stocks at landscape level are around 400 m³ per hectare. According to the FAO (2015), there are only nine countries in the world where the wood stocks in the forests exceed 300 m³ per hectare. Germany is one of them. The highest stocks are in New Zealand, with a stock level of 392 m³ per hectare.

A study by Knoke (1998) in 13 plenter forests of the Bavarian Forest revealed a stock of 408 m³ per ha. Plenter forests are characterised by having trees of all ages occurring side by side. This result is also confirmed by a study by Schulze et al. (2022). They analysed inventory data from several hundred forest stands and determined average stocks of just over 400 m³, although this also included deadwood stocks. According to the National Forest Inventory of 2012 (BWI 2012), the wood stock in Bavaria's forests was 396 m³/ha. In our assessment, a further increase in stocks would increase the risks of calamities. The age structure of the forests shows that many forests are now ready for cutting, or will soon be ready for cutting.

Contrary to our assessment given here that the possibilities of a further increase in the wood stock are limited, the federal government has, by implementing Section § 3a of the [German] Climate Protection Act, decided to increase the forest carbon stock. By 2045, the aim is to achieve a sink capacity of 40 million tonnes of carbon dioxide equivalent - 2.4 times more than in 2020. However, in the Climate Protection Report of 2021, the German government wrote: "According to forecasts, the sink capacity of the forests could decline due to the age structure of the forest stands and weather-related damage to the forest, and as a result of changes in wood use." So the gap between target (wish) and reality has already been recognised.

What is more, we also believe that the conversion of the forests to more climate-resilient forests will require not less, but more timber utilisation. Scientists from the LWF’s Department of Forestry Technology, Business Management and Timber used the software WEHAM to model a “forest conversion scenario”. This scenario shows that wood utilisation could even increase significantly in the short term and exceed the wood increment. This would lead to a slight decrease in the standing wood stock in Bavaria. However, if the additional utilisation is not carried out in accordance with a plan, additional utilisation or increased dieback are to be expected anyway as a result of calamities.

There are calls to stop using large areas of forests commercially in the interests of nature conservation (see National Biodiversity Strategy, EU Biodiversity Strategy). To support this goal, nature conservation interests are often mixed up with those of climate protection. The Federal Government's "Natural Climate Protection" action campaign talks of synergies between climate protection and nature conservation, thus highlighting the concordance between nature conservation and climate protection interests. It is for example claimed that more carbon is stored in unmanaged forests.

The aforementioned study by Schulze et al. (2022) does not support this thesis. In a comparison of the stocks (including deadwood) of unmanaged and managed stands, there were no significant differences in the wood stocks in coniferous stands. In the deciduous forests, on the other hand, the wood stock on unmanaged stands was somewhat larger. However, in both cases there was significantly more wood increment in the managed stands - the expected sink effect of unmanaged forests is thus questionable. In addition to this, forest carbon storage in Bavaria has probably almost reached its maximum, as already shown.

It is also the case that a maximisation of carbon storage cannot meet all climate protection requirements at the same time. The four requirements of the Paris Agreement are a reduction in the growth rate of atmospheric CO2, a reduction in the radiative imbalance at the top of the atmosphere, a reduction in the temperature of the near-surface air layer - and the latter without a decrease in precipitation.

Model calculations by Luyssaert et al. (2018) for Europe showed that no form of forest management can meet these requirements simultaneously. One of the scenarios envisaged a doubling of unmanaged forest areas - and yet the climate effects of all management forms considered were marginal. The authors therefore suggest that in the coming decades, the main task of forest management in Europe should not be climate protection, but the adaptation of forests to the future climate. This should ensure the continued provision of timber and the environmental, social and cultural services provided by the forest, while at the same time helping to prevent the knock-on effects of climate change such as fires, strong winds, pests and drought.

Climate-washing

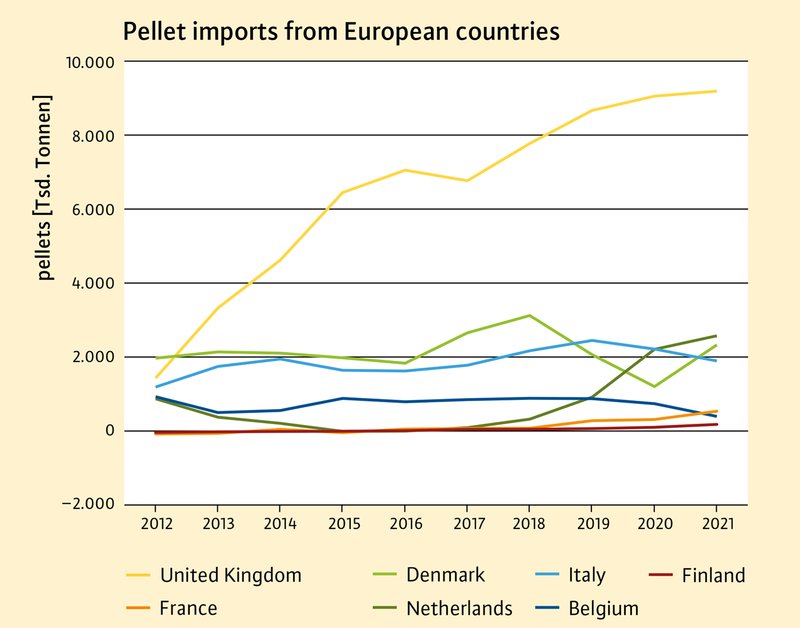

Climate-washing is the term used to describe the “greenwashing” of climate balances. In the Framework Convention on Climate Change, countries worldwide have agreed to account for their greenhouse gases separately by sector, and each state for itself (source and territory principle). The EU regulation that governs European reporting (the so-called Monitoring Regulation) states that: "The emission factor of biomass shall be zero". This statement has led to some European countries, especially coastal countries, converting their coal-fired power plants to pellets and importing the pellets from overseas (Fig. 7). In the accounting of CO2 emissions from fossil fuels, this took pressure off their “Energy” sectors.

They do not have to take the effects of pellet use into account for their forest carbon storage. This happens at the expense of the countries supplying them from overseas, who ought to include the impact that the supplying of pellets has on forest carbon stocks in the accounting for their LULUCF sector. This is done on the basis of forest inventories and is costly. The concern of many scientists, however, is that the supplier countries do not account for their forest carbon stocks correctly. Their criticism is particularly strong when it is not residual wood that is being used there, but whole trees that are being harvested exclusively for pellet production.

By contrast, in Germany pellets are usually produced from wood residues left over from the processing of raw logs into harvested wood products. This procedure is not criticised by the scientific community. Germany is self-sufficient in pellets, and in fact exported a net total of 431,000 tonnes of wood pellets in 2021. The accusation of climate washing against Germany would thus be unjustified.

Cascade utilisation

Another argument against the use of wood for energy is that wood is a scarce resource. A material use of the wood would keep the carbon bound in the harvested wood products for longer. The substitution of wood products for products such as steel or bricks, production of which is more energy-intensive, also helps to save fossil fuel energy (material substitution).

These statements are all correct. However, not all trees or tree parts are suitable for material use. Moreover, the volume demand is not sufficient everywhere for it all to be put to material use. Very small-diameter or crooked wood is not suitable for sawmills. This wood could be used for the production of chipboard or paper and pulp. Graphic paper consumption has decreased in recent years, so that the demand for raw wood for paper production has fallen in Bavaria. Raw wood consumption for chipboard production is also declining in Germany. It thus seems more appropriate to use the low-diameter wood for energy purposes close to the site rather than to transport it to sawmills some distance away. Tree parts such as spruce crowns are also often only chopped and used as energy for forest protection reasons, i.e. in order to minimise the breeding space for bark beetles and other harmful insects.

Wood is stored energy

When comparing wood with other renewable energy sources, people often overlook the fact that wood represents stored energy that can be called up at any time. If not consumed immediately, electricity generated by wind or photovoltaics has to be stored in batteries or pumped-storage hydroelectricity reservoirs, or used to produce hydrogen. In all cases, considerable losses are made during the conversion of the power.

Wood is a homegrown energy resource and thus crisis-proof

The war in the Ukraine has shown us the extent to which Germany is dependent on other countries for fossil fuels. These countries are often not democratically governed, and they are prepared to use their resources as a means of exerting pressure on others in order to achieve political aims. It is understandable if people who are worried about how they are going to keep warm next winter are increasingly switching to wood energy. Although the prices for some wood fuels have also risen in recent years - indeed sharply in recent months - they are still much less volatile and erratic than oil prices.

Furthermore, wood energy can be procured decentrally from regional suppliers, and people can also reduce costs by doing some of the work themselves, e.g. by processing and in some cases felling their own firewood. Wood energy is therefore comparatively inexpensive and an alternative to other energy resources, especially for low-income households or structurally weak regions.