Wood can be produced CO2-neutrally, used several times as a material, transported and stored in various forms, and used as heat, electricity and fuel. Not least, it can bridge gaps in solar and wind energy production, as it is available all year round. All this shows that wood is a highly flexible source of energy.

Scientists at the Swiss Federal Institute for Forest, Snow and Landscape Research WSL, the Paul Scherrer Institute PSI and other institutions have calculated the energy potential of Swiss wood, and made further advances in technologies for its combustion and conversion into electricity and fuels. They have also investigated how bioenergy can best be integrated in the Swiss energy system.

The authors of the White Paper on Wood (PDF) emphasise that “energy wood is of greater importance than its comparatively low potential would suggest”. The paper summarises the results of the Federal Government's long-term energy research programme "Biomass for Swiss Energy Future" (SCCER Biosweet), which involved up to 15 research groups and dozens of industry partners.

Fig 1 - Wood grows continuously in the forest. The average annual increment growth in forests in Switzerland is around 10.8 million m3; this corresponds to a primary energy quantity of approx. 85 petajoules (PJ). Only part of the increment can be used economically and is harvested. Priority here is given to material use, for reasons of climate protection and value creation. Ultimately, around two million cubic metres of wood are used directly from the forest for energy, containing approx. 19 PJ of primary energy. Sources: Swiss Statistical Yearbook of Forestry 2022, Thees et al. 2023

Unused but limited potential

Currently, wood energy accounts for about 5 per cent of the total final energy consumption in Switzerland, namely about 40 petajoules (PJ) per year. That is slightly more energy than the city of Zurich needs in a year. The WSL bio-energy experts calculated that this share could grow by a maximum of one third to 54 PJ - and be economically and ecologically sustainable.

Energy wood can originate directly from the forest and open land, but it can also consist of residual wood from carpentry and sawmills, or wood that has already been used (referred to as waste wood). The most untapped potential (5 to 10 PJ) is still in forest wood. “Wood, as a valuable but limited source of energy, requires efficient use,” emphasises Oliver Thees from WSL, lead author of the report.

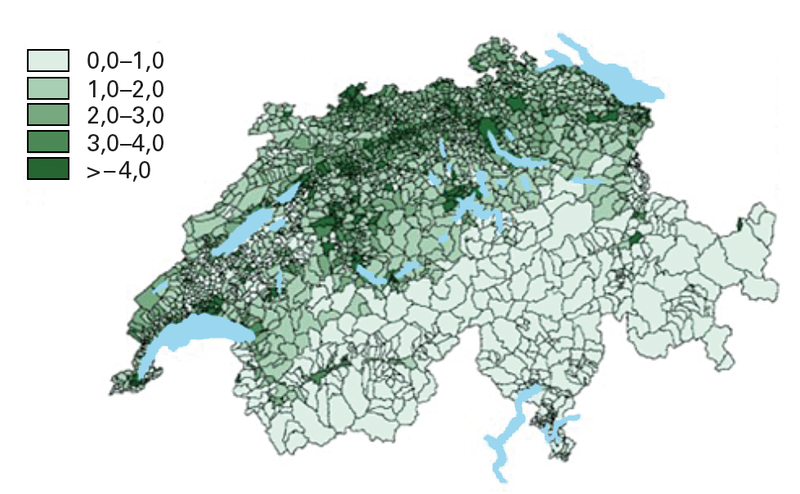

Fig. 2 - Ecologically and economically sustainable energy wood potentials per municipality in 2014: relative values in terajoules (1 TJ = 0.001 PJ) per km2and year. The potentials include all wood biomass that can be used for energy: forest, field, residual and waste wood. Map with absolute values.

From a climate protection perspective, wood should not, if possible, go straight from the forest into the wood burner. It should first be used to make houses and furniture, chipboard or insulating materials, and can be burned later. This is called “cascade use”, although it is not yet as well established as it could be.

Aircraft fuelled by wood

Currently, 95% of the valuable energy wood is used to generate heat to heat rooms. For maximum energy production and CO2 savings, wood should be used differently on a larger scale than it is today.

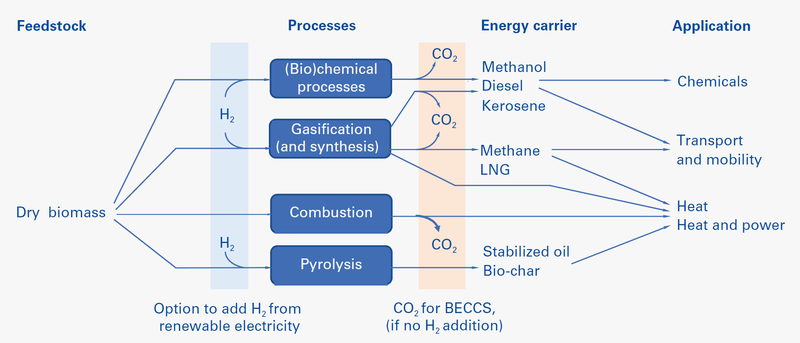

In industry, wood can be used to generate the heat necessary for high-temperature processes, for example in the form of steam. Or it can be used to produce gaseous and liquid fuels - for aircraft, for instance. The waste heat and CO2 produced during the conversion process should be captured and used. This helps the CO2 balance and compensates for other emissions, such as those from agriculture, which are unavoidable. The conversion technologies developed in the research programme improve the efficiency and CO2 balance of such applications, although not all are yet ready for the market.

Electricity can also be generated from energy wood in combined heat and power plants. Especially in winter, this would be the next best use, to bridge the winter electricity gap. If wood is to be used to heat buildings, large plants should ideally and where possible be used, connected to a district heating system. These emit fewer pollutants and are more efficient than a large number of small units. “We have developed new processes for converting wood into fuels and energy and brought them closer to the market, thus contributing to the success of the Swiss energy transition,” says Oliver Kröcher from the Paul Scherrer Institute PSI.

Stabilising the electricity grid

As energy wood is so versatile in its uses, it can be seen as a “wild card” for shaping the energy transition. It can stabilise the energy supply and the electricity grid, as wood can be stored and used when needed to offset peak loads in the grid.

More efficient wood use will not be achieved by technological means alone. There is still work to be done in research, business and politics: wood usage chains must be examined and optimised. A basis for the practical implementation of these complex technologies must be established. Last but not least, political measures can be introduced to steer the use of wood, for example through targeted incentives for efficient combustion plants, or through the establishment of an obligation to secure the energy supply of the plants right from the project development stage.

Scientific original publication

Thees O., Erni M., Burg V., Bowman G., Biollaz S., Damartzis T., … Kröcher O. (2023) Wood fuel in Switzerland: energy potential, technology development, resource mobilization, and its role in the energy transition. White paper. Swiss Federal Institute for Forest Snow and Landscape Research WSL. 34 p. https://doi.org/10.55419/wsl:32791