A case study of 60 year old check dams

Timber is a valuable material used for check dams in mountain torrents. However, due to natural decomposition processes mechanical stability can decline over the years. In an on site case study scientists examined the logs of three check dams which were built around 1940. They bent the logs until they failed. However, two thirds of the tested logs still had a higher ultimate bending moment than was assumed from the original design.

Timber has a long tradition as a building material in torrent control. Today it is mainly used for structures in small mountain torrents with low debris flows. Timber has various advantages over other building materials such as concrete or steel.

On the one hand it can usually be prepared in the vicinity of the building site; on the other hand it is relatively cheap, easy to work with and, although light in weight is has considerable strength. Due to this timber can be used on less stable ground where concrete check dams would need elaborate foundations. Compared to concrete structures wooden check dams are less susceptible to deformation and ground movement. This can be a deciding advantage in unstable areas.

How durable are wooden check dams?

Out in the open untreated timber is subject to natural decomposition processes caused by fungi and other micro-organisms. Timber which is constantly in contact with soil and water is considered to be especially at risk. However, such conditions are typical for timber which is used for check dams. Therefore, the question of the long-term bearing capacity arises.

Up to present research on the long term performance of check dams has been based on a visual assessment of functionality and decomposition processes. The actual strength of the used logs remained an unknown factor. However, changes in timber strength, which occur due to the specific conditions found in mountain torrents, are of central importance for the bearing capacity. Only knowledge about this development allows conclusions to be made about the expected long term safety of timber structures used in torrent control.

Assessment of the bearing capacity

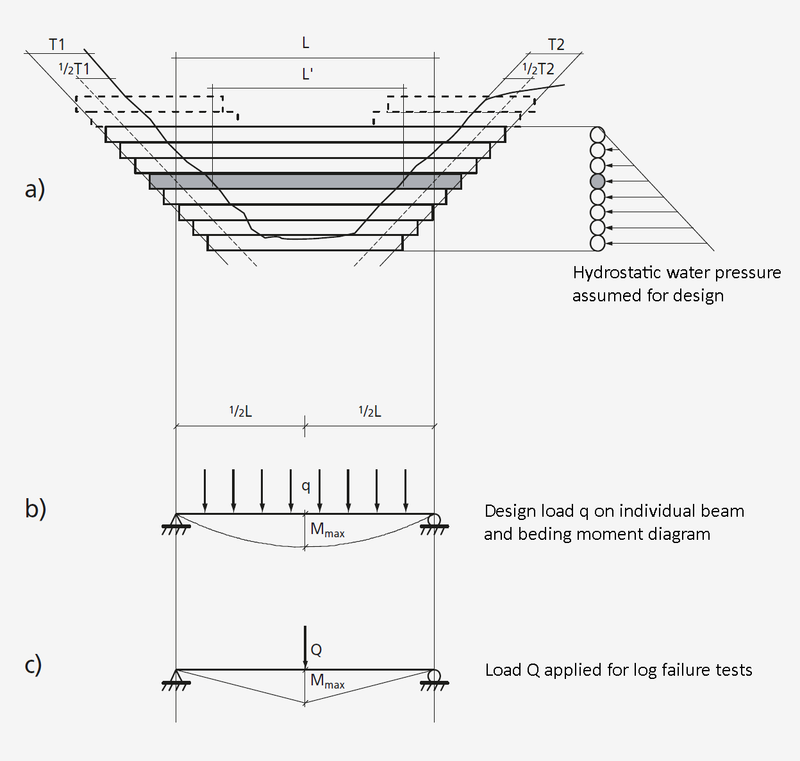

Wooden check dams have to be designed to carry the same loads as those built out of reinforced concrete. Assessment of the bearing capacity is usually based on the Swiss timber design code (SIA). The design of individual logs is based on the decisive load resulting from hydrostatic water pressure under the maximum water level of a non back filled dam. (Fig.2a). With a steep back fill (e.g. dams in scree gullies) the soil pressure must also be considered.

The static system for a single log used in a dam corresponds approximately to that of a simple beam (Fig. 2b). The nominal lateral abutments are assumed at half of the corresponding bonding depths. This static model gives the maximum bending moment Mmax = q·L2/8 at midspan, where q is the force resulting from the hydrostatic water pressure and L the nominal log span between the nominal abutments.

Fig. 2 - Schematic presentation of the tested dams. a) The effect of hydraulic pressure under maximum water-head without any back fill. b) q is the uniformly distributed load on each log caused by the hydrostatic water pressure. The maximum bending moment Mmax occurs at midspan. c) During the test the load Q, applied by a wire rope attached at midspan resulted in a triangular moment diagram with the maximum bending moment Mmax also at midspan.

Failure tests in bending

First failure tests on an approximately 60 year old check dam showed that the original logs had a relatively high strength in bending. The aim of a more elaborate experiment was to get results concerning the bearing capacity of dams which were built several decades ago.

The tests were carried out in a stream in full shade on the western slope of the Zimmerberg (parish of Hirzel, canton of Zürich). According to the local forestry service the one-walled spruce and fir check dams were constructed between 1939 and 1945. In their opinion the whole structure was in need of replacement at the time of the tests in autumn 2000 and it was planned to replace them in 2001. For the tests the scientists chose three dams at 650 m above sea level. (Fig. 1).

The set up for the tests was consistent with the above described model. In order to be able to test the logs without the influence of vertical joints the scientists first cut through the nails connecting the logs. The load Q was applied at midspan of each log using a wire rope. (Fig. 2c). This produced – comparable to the design model – a maximum bending moment at midspan Mmax=Q·L/4. The scientists calculated the nominal span L using the formula L=L’+1/2(T1+T2), whereas the visible span L’ was measured before the test and the horizontal bonding depths T1 and T2 afterwards (comp. Fig. 2a). The loads were applied to the individual logs until they failed using a tractor driven winch. (Fig. 3).

The force Q was registered at intervals of 0.25 seconds by dynamometers installed along the wire rope and stored in a data logger. Thereby, the load increase as well as the ultimate load Qu could be measured. After the tests the diameter of every log was measured at midspan (at the point L’/2) and the number of cross sections that had failed were recorded. The scientists tried to record the sequence of failed cross sections visually. However, these occurred so quickly one after another that they could not be distinguished by the naked eye.

Results

In total 14 logs, seven from the first, four from the second and three from the third check dam were tested and analysed. Eleven logs failed at midspan as well as in the region of both abutments; two failed at midspan and at one abutment and one failed only at midspan.

The case study showed that the median of the bending moment Mu of the logs used in the 60 year old check dam was greater than the corresponding calculated value for the ultimate bending resistance MR by a factor of 1,2. In available literature spruce and fir wood are generally judged as being less durable and as having an extremely short life span when in contact with soil and water. The determined bending moments at failure proved however that, in the case of the studied objects, even after many decades of use sufficient timber strength can be expected. It should be taken into account when interpreting these results that the tests did not completely comply with the model used for structural design. The following list contains some aspects which could influence the test results:

- Sample material

- Statical system

- Experimental procedure

- Evaluation approach

Conclusions

The question of long term safety not only arises in the case of wooden check dams. The decisive loads on supporting structures used in natural hazard protection, as well as their mechanical properties, can change. In the above case the bending moment Mu (at failure) of two thirds of the original logs was greater after 60 years than the predicted calculated limit of the ultimate bending resistance MR ("calculated bending moment at failure"). Compared to the permitted bending moment Mzul in accordance with SIA 164 (1992) resp. SIA 265 (2003) all logs fulfilled the safety requirements, in spite of being used over decades in the typical periodically wet conditions found in torrents.

It should also not be forgotten that the life span of a wooden check dam is also affected by processes other than natural decomposition, such as mechanical damage caused by bed load transport, debris flow or by soil movements. Assuming that timber check dams should be renovated after approximately 40 years then the present results show that the assessment of the bearing capacity in accordance with SIA 614 (1992) resp. SIA 265 (2003) is perfectly adequate.

The results of the above presented case study have to be confirmed by further tests. Of special interest are also dams in channels with less favourable conditions, e.g. in very sunny positions and /or with only temporary water flow.

Translation: Dawn Meister, Stallikon

Literature

- Albert Böll, Werner Gerber, Frank Graf, Christian Rickli (1999): Holzkonstruktionen im Wildbach-, Hang- und Runsenverbau. Birmensdorf, Eidgenössische Forschungsanstalt für Wald, Schnee und Landschaft. 60 S., ISBN 3-905620-76-6.